GMP Cleanroom Cleaning Services

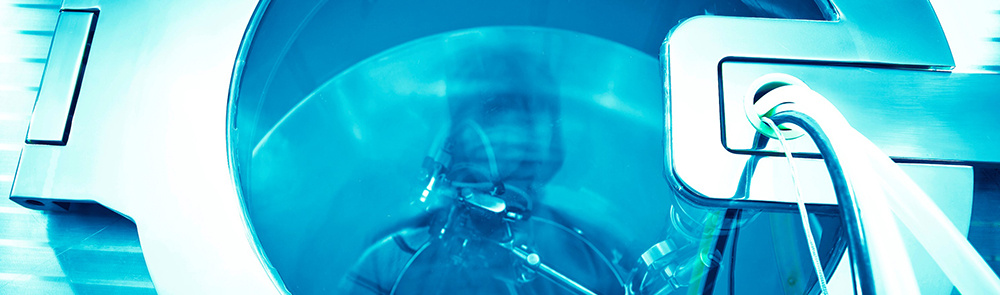

Specialized Contamination Control for Regulated Environments

Why Internal Staff and Janitorial Companies Struggle with GMP Cleaning

Lack of Specialized Training

Traditional janitorial staff and even facility teams lack training in aseptic techniques, cleanroom gowning protocols, proper application of pharmaceutical-grade disinfectants, and contamination control principles critical to GMP environments.

Experience

With over 17 years servicing hundreds of GMP facilities throughout New England -- we ensure your Clean Room facility is serviced by personnel who understand Clean Room requirements, are continuously validated via routine training programs, and understand the critical impact cleaning has on product quality and compliance.

Compliance & Audit Risk

Without documented training, validated procedures, and contamination control expertise, facilities face increased risk of environmental monitoring failures, regulatory deficiencies, and failed audits—jeopardizing product quality and patient safety.

Why Internal Staff and Janitorial Companies Struggle with GMP Cleaning

nanoCLEAN has brought together the strengths of specialized cleanroom cleaning for pharmaceutical, medical device, semiconductor, aerospace, and other high-technology companies to create a service that incorporates training, cleanroom-approved equipment, and microcleaning with a comprehensive knowledge of contamination control.

Our state-of-the-art cleaning and decontamination procedures result in proven Quality Ratings that are unparalleled in the industry. We follow the concepts of ISO 9001 quality management systems in order to provide parallel performance and quality measurements that meet all customer and regulatory requirements.

Working as partners, nanoCLEAN becomes an extension of your "clean team." As your cleanroom experts, we offer our local and regional resources and the expertise of our Technical Advisory Board.

Our highly trained technicians undergo:

- Continuous comprehensive cleanroom fundamentals and GMP principles training

- Hands-on practice with cleanroom-approved equipment and materials

- Aseptic technique certification and cleanroom gowning protocols

- Site-specific SOP training tailored to your facility requirements

- Regular audits, competency assessments, and continuing education

We Take Your

Cleanroom:

From Clean to

Pristine

Services we offer

- Routine Daily Technical Cleaning & Disinfect

- Hospital Pharmacy / 797 Cleanings

- One-time Decontamination Projects

- Cleaning SOP Development

- Cleanroom Protocol Audits & GAP Analysis

nanoCLEAN has brought together the strengths of specialized cleanroom cleaning for the pharmaceutical, medical device, semiconductors, aerospace, and other high-technology companies to create a service that incorporates training, cleanroom-approved equipment, and microcleaning with a comprehensive knowledge of contamination control.

Our state-of-the-art cleaning and decontamination procedures result in proven Quality Ratings that are unparalleled in the industry. We follow the concepts of ISO 9001 quality management systems in order to provide parallel performance and quality measurements that meet all customer and regulatory requirements.

Working as partners, nanoCLEAN becomes an extension of your “clean team”. And as your cleanroom experts, we offer our local and regional resources and the expertise of our Technical Advisory Board.

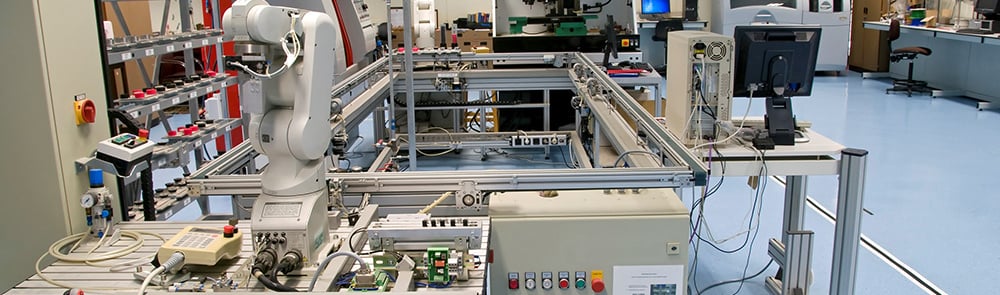

Industries We Service

Pharmaceutical

Compounding & Hospital Pharmacies

Biotechnology

Medical Device

Semiconductor

Aerospace

Labs

Cold Rooms

Highly Controlled Environments